What is Vertical Stiffness?

Vertical stiffness refers to a wheel's resistance to deformation under a vertical load. In simpler terms, it measures how much a wheel flexes when you ride over bumps or uneven surfaces. A wheel with high vertical stiffness will maintain its shape better under stress, leading to improved power transfer and responsiveness. Conversely, lower stiffness can enhance comfort by absorbing shocks but may compromise performance.

Why Vertical Stiffness Matters

- Performance: A stiffer wheel can transmit more power to the road, making it more efficient for sprinting and climbing.

- Handling: Stiff wheels provide better feedback and control, especially during cornering.

- Comfort: Finding the right balance between stiffness and compliance is key for a smooth ride, particularly on rough terrain.

At 8LIEN Bike, we prioritize vertical stiffness in our wheels. Before mass production, we conduct rigorous vertical testing for all our models. Below are the results from these tests:

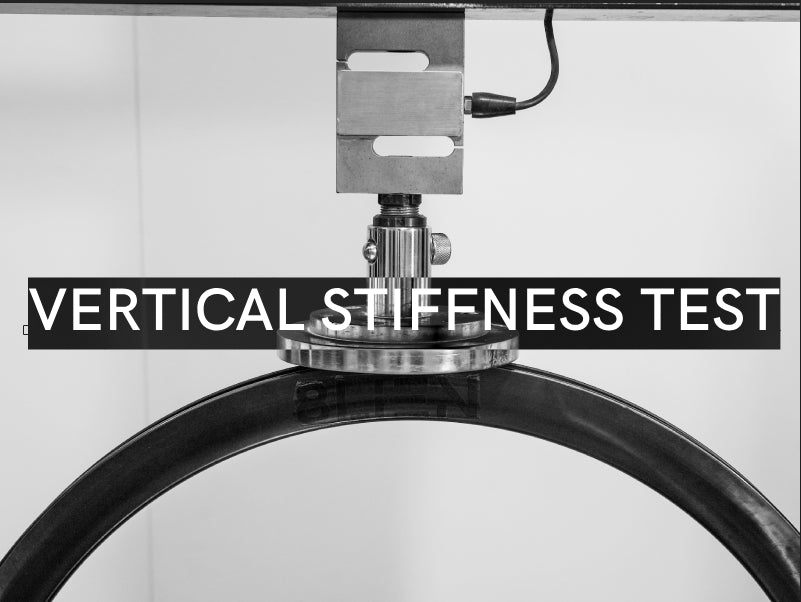

Testing ProcessSetup: A secure test rig holds the wheel in place while simulating the conditions it will face during a ride.

Measurement Tools:

- Load Cell: Measures the force applied to the wheel.

- Displacement Gauge: Tracks how much the wheel deflects under the load.

Testing Steps:

- Gradually apply a known vertical load to the wheel.

- Record the force and the corresponding displacement at various load levels.

Data Analysis:

| Size | Model | External Width | Depth | Load Max | Weight | Rim Condition |

| 700C | L5 | 28mm | 21mm | 50kgf | 400g | New rim that has passed flatness and roundness tests |

| No. | MAX FORCE | DEFLECTION | ABSORING | STENGTH | TIME | Deflection |

| (kgf) | (mm) | (kgf.mm) | (kPa) | (min) | (mm) | |

| 1 | 40 | 1.26 | 30.39 | 6225.61 | 0.12 | 1.36 |

Conclusions

L5 (21mm internal, 28mm external widths, 45mm depth) flexs vertically 1.26mm to 1.36mm under a load of 40kgf.